LG Energy Solutions will invest 7.2 trillion won to build the largest battery factory in North America based on single production. It is a large-scale investment to respond to the demand for batteries in the finished car industry.

On the 24th, LG Energy Solutions announced that it would invest a total of 7.2 trillion won to build a new cylindrical battery plant and energy storage system (ESS) production plant in Queen Creek, Arizona, USA. Both factories will start construction this year. The total plant production capacity is 43GWh (gigawatt hour), which is the largest among global battery independent production plants located in North America.

LG Energy Solutions has significantly increased the amount of investment compared to the previous plan. LG Energy Solutions announced a plan to build an 11GWh battery factory by investing 1.7 trillion won in March last year, but went into full review within three months. This is because the investment cost has soared due to inflation and economic recession.

However, through a board of directors meeting on the 24th, it resumed the construction of its own cylindrical battery production plant in Arizona, investing 4.2 trillion won to build a 27GWh plant a year, greatly expanding the scale of investment and production capacity. It is capable of producing 350,000 high-performance pure electric vehicles. 3 trillion won will be invested separately on the same site to build a 16GWh ESS lithium iron phosphate (LFP) battery production plant. It is the first global battery company to build a battery production plant exclusively for ESS.

Among domestic battery makers, LG Energy Solutions is the first to build a cylindrical battery production plant in North America. Even in terms of overall battery makers, it is second only to Panasonic, which supplies most of its production to Tesla.

The cylindrical battery factory aims to be completed and mass-produced in 2025. The battery industry expects that the flagship model (2170 cylindrical battery) produced at this factory will be supplied to Tesla. Currently, Tesla is receiving cylindrical batteries from LG Energy Solutions, CATL of China, and Panasonic of Japan. Among them, Panasonic already has a production base in the US, and CATL is not free from US regulations on China.

Supply to North American electric vehicle startups that use cylindrical batteries such as Lucid is also expected to increase. The global cylindrical battery market is expected to expand from 36.8 trillion won last year to 70.2 trillion won in 2026.

At the battery factory dedicated to ESS, pouch-type LFP batteries independently developed by LG Energy Solutions are produced. Its goal is to start construction this year and mass-produce batteries in 2026. According to market research firm SNE Research, the North American ESS market is expected to grow more than 10 times from 14.1GWh in 2021 to 159.2GWh in 2030. LG Energy Solutions plans to compete with price competitiveness by saving logistics and customs costs through local production.

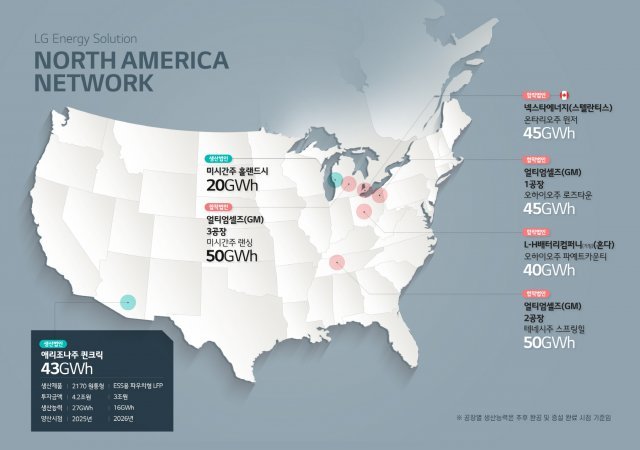

North American production base status of LG Energy Solutions. Provide LG Energy Solution

North American production base status of LG Energy Solutions. Provide LG Energy SolutionThrough this investment, LG Energy Solutions will be equipped with a new independent production base following the existing Michigan independent production plant, three factories established in joint venture with General Motors (GM), Honda Joint Venture (JV), and Stellantis JV. If all are put into operation, the total production capacity will reach 293GWh. In accordance with the implementation of the Inflation Reduction Act (IRA) in the United States, subsidies for electric vehicles have been expanded and support for eco-friendly energy has been strengthened.

Source: Donga

Mark Jones is a world traveler and journalist for News Rebeat. With a curious mind and a love of adventure, Mark brings a unique perspective to the latest global events and provides in-depth and thought-provoking coverage of the world at large.